In the application of electrical automation, pneumatic technology represented by compressed air and vacuum is the best means to achieve low cost and high reliability.

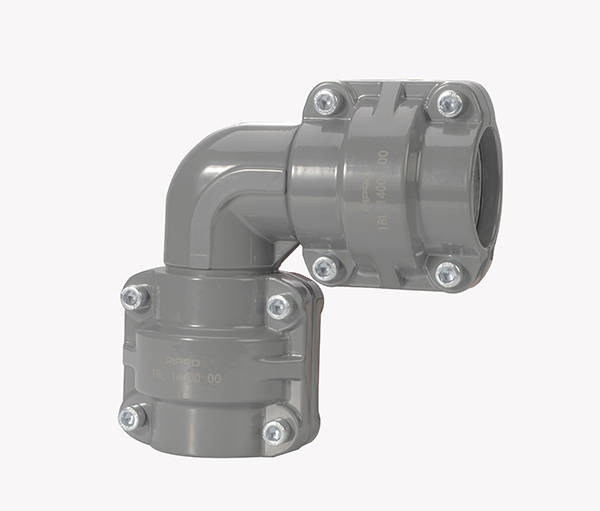

The aluminum alloy pipeline pneumatic system is mainly composed of power system, delivery system and executive elements. The power system, such as air compressor and vacuum pump, is like the heart and lung of the human body, while the pipeline system is like the blood vessel and trachea that deliver blood and oxygen. The two complement each other. Pipeline system plays an important role in it.

As the main component of carbon steel pipe of aluminum alloy pipeline is iron, this element is easy to react with water and oxygen in the air to produce iron oxide (rust). This material will cause cylinder wear and equipment damage and unnecessary losses to the user when it is transmitted to the cylinder and production equipment with compressed air. If the air source is in direct contact with the product, the quality will be reduced, and the impact will be more serious if it is food products. Even if the filter triplet is adopted, as rust is a solid impurity, it is very easy to adsorb on the filter material, resulting in the short service life of the filter material and the pressure drop.

Because of the disadvantages of traditional pipeline in practical application, a new type of fluid gas transmission system - aluminum aluminum alloy pipeline system came into being. As early as around 2000, European and American enterprises have been widely used in the transmission of compressed air pipes, vacuum pipes, and inert gases such as nitrogen. The earliest application case in China was installed in Hangzhou Daily printing plant in 1996, and has been used for more than 20 years.

+86 18504207240

Service hotline : +86 18504207240

E-mail:xin@piproline.com

Address:East of Fujiagou Ores, Group 7, Xiajia Hezi Village, Gezhenbao, Ganjingzi Dist, Dalian, Liaoning, China