Physical principles determine that compressed air is an expensive energy source so far. At the same time, the law of thermal dynamics also clearly tells us that compressed air cannot be obtained without consuming heat energy. After a long time of operation of the compressor, it is very important to recover and reuse the heat energy when compressing the air.

Why is heat recovery in the production of compressed air a quick return investment? In terms of energy, compressed air is a very hot topic. Limited resources, strict environmental protection regulations, limited CO2 emissions and rising energy prices are the driving forces of energy efficiency project construction. On the one hand, the carefully designed process, including the use of frequency conversion technology to adjust the speed of the air compressor, making the air compressor work near a good working point as much as possible, and the proper power reserve to ensure the safety of the enterprise's production process, have laid a good foundation for the project. On the other hand, when the compressor increases the air pressure, it increases the air temperature, which also brings great potential for heat energy recovery and reuse. Based on the cost-benefit considerations of enterprises, enterprise users are increasingly concerned about the issue of thermal energy recovery and reuse.

The return on investment of thermal energy recovery and reuse is very high, and the total investment can be recovered in less than two years. Why does the heat recovery of compressed air have such potential? This article will answer in detail.

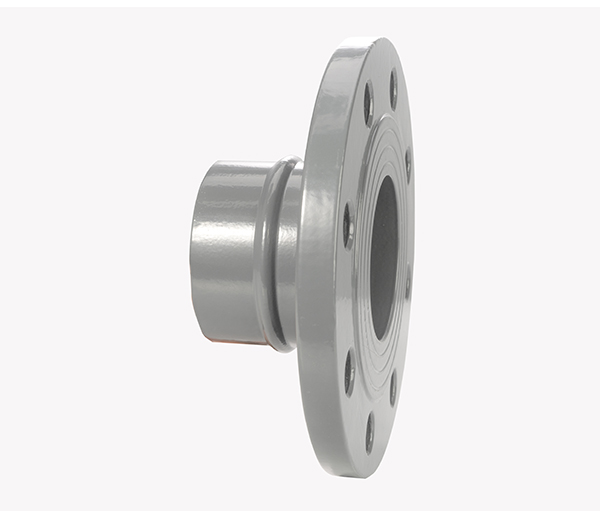

The compressed air passes through the cooler tubes of the heat exchanger, and the cooling water flows in the tubes in reverse. The cooling tubes of the sheet design ensure effective heat transfer and reduce pressure loss.

1. Utilization of thermodynamic laws

According to the laws of thermodynamics, when the air in the closed space is compressed, the temperature of the gas will rise. When the gas is compressed in the closed space, the distance between the air molecules will be shortened, and the friction generated will increase. According to these thermodynamic principles, combined with the efficiency of each working point of the air compressor, the temperature after air compression can be calculated.

The temperature also depends on the compression ratio. For example, when the intake air temperature is 20 ℃, the compression ratio is 3, and the isentropic efficiency of the compressor is 74%, the temperature of air compression will reach 166 ℃. The higher the temperature, the wider the range of waste heat utilization.

In thermodynamics, the mass of heat is described by Carnot coefficient, that is, the ratio of the temperature of waste heat and the heat emitted, that is, the utilization rate of waste heat. The heat contained in the gas usually accounts for about 85% of the total heat that can be recycled, and the remaining 15% is roughly evenly distributed to the drive motor consumption, mechanical consumption and thermal radiation in the hot air compression stage.

Energy balance of typical screw air compressor

2. Thermal energy use

In the space with heat recovery and reuse measures, the remaining 15% of the total heat that can be recycled can also be directly used, which can be used as the heating heat for the nearby offices and production workshops.

In order to make use of these heat, unlike the conventional case where the hot gas is cooled in the compression stage, the silencing stage and the duct system inside the silencing hood, the screw compressor is equipped with an exhaust pipe through which the air is discharged. The temperature of the exhaust gas in the central exhaust pipe is between 30 ° C and 60 ° C. the exhaust gas in this temperature range is returned through the branch pipe for indoor heating. At the same time, this heating system uses the gate valve to control the specific heating temperature of each different space.

The heat energy of pure waste gas can be effectively used for indoor heating, but the appearance of shell and tube heat exchanger opens up a Xintiandi for the utilization of high-temperature waste gas energy. Therefore, this technology is also recommended for the technical transformation of the air compressor station to significantly improve the energy utilization efficiency of the air compressor equipment.

The compact shell and tube heat exchanger is installed on the pressure side of the air compressor. The shell and tube heat exchanger can be easily and conveniently integrated into the original compressed air supply system. The design of the shell and tube heat exchanger is based on the flow characteristics of the internal medium. With the increase of the pressure of the exhaust pipe system, the power loss is only 2%, which is almost negligible compared with the saving brought by the heat recovery.

The shell and tube heat exchanger brings many new possibilities of heat energy utilization. It is typical to heat the heating system, shower and toilet water and industrial water.

+86 18504207240

Service hotline : +86 18504207240

E-mail:xin@piproline.com

Address:East of Fujiagou Ores, Group 7, Xiajia Hezi Village, Gezhenbao, Ganjingzi Dist, Dalian, Liaoning, China