The tools and raw materials used in the use of super pipes include special hot-melt machine, aluminum alloy energy-saving pipe, matching pipe fittings, matching cutter for marking pen peeling, saw bow and degreasing agent.

There are also cartons for collecting waste aluminum alloy sheets and waste pipes of super pipes. The aluminum alloy environmental protection and energy-saving pipe system is a very important process in the construction of the building water supply system. Each project will be supported by professional engineers for on-site guidance to ensure the quality of installation. The specific operation is as follows.

Super pipeline construction scheme conditions, environment, construction technology, materials, mechanical tools and supplies can ensure normal construction. The construction personnel must be familiar with the design, installation and use procedures of aluminum alloy energy-saving pipe products, and the necessary posts also need to work with certificates.

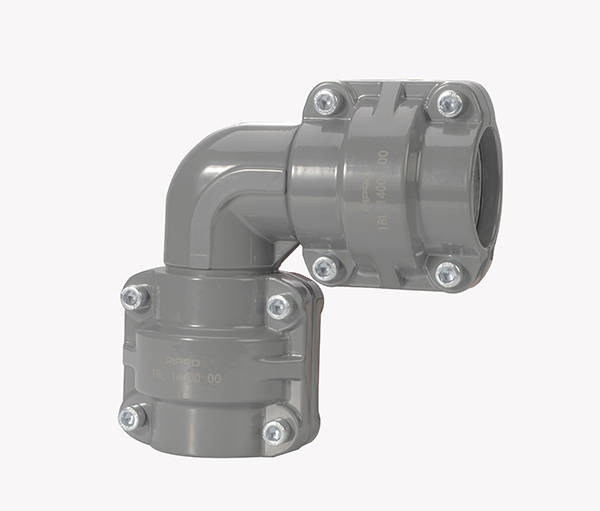

Pipe fittings and pipes should not be exposed to the sun for a long time. In order to avoid bending of pipes during hospitalization, they should be stacked flat. When handling pipes and pipe fittings, be sure to handle them with care to avoid oil contamination, and do not conduct violent impact. It is strictly prohibited to transport them by throwing, dropping and falling. Before connecting the aluminum alloy energy-saving Pavilion, it shall ensure that the inner wall of the used pipes and fittings is smooth and flat, free of cracks, peeling and obvious transverse grooves, and the color should be basically the same.

400-1818-935

Service hotline : 400-1818-935

E-mail:piproline@163.com

Address:Lantian Industrial Park, Ganjingzi District, Dalian